When you need to fill a large container with water or gas, what do you do? You go to the store and buy a pump. And that’s not always the best solution. In fact, there are many different pumps on the market that cater to specific needs. Which pump is best for high pressure? This is a question that plumbers and other professionals need to answer on a regular basis. And the answer can be rather complicated. In this blog post, we will explore the different types of pumps and their respective uses. We will also explain which pump is best for high-pressure situations and why. So whether you’re a homeowner who needs to change a tire, or a professional who needs to install a new water line, read on to learn everything you need to know about pumps.

What is a high-pressure pump?

A high-pressure pump is a machine that uses pressure to move fluid from one location to another. They are used in a variety of industries, including oil and gas, chemical manufacturing, and food processing. There are several different types of high-pressure pumps, each with its own advantages and disadvantages.

The three most common types of high-pressure pumps are screw compressors, diaphragm pumps, and vane pumps. Screw compressors use circular screws to increase the pressure against the moving parts. This type of pump is generally faster than diaphragm or vane pumps, but they can be less efficient at higher pressures. Diaphragm pumps use air or water as the working fluid and a series of rubber discs to create the pumping action. They are slower than screw compressors but more efficient at higher pressures. Vane pumps use vanes (or blades) to increase the speed and efficiency of the pump while reducing noise levels.

Types of high-pressure pumps

There are a variety of high-pressure pumps on the market, each designed for a specific use. Here’s a look at four of the most popular types:

1. Diaphragm pump: This type of pump uses a diaphragm to move the fluid through the pump. The diaphragm is usually made out of metal or plastic and is placed between two chamber plates. When the pressure in one chamber increases, the diaphragm moves up and pressurizes the second chamber, which then forces the fluid through the pump. This type of pump is ideal for applications that require high pressure but the low volume (like vacuum cleaners).

2. Axial flow pump: This type of pump uses an impeller to rotate, which causes gas or liquid to flow along the axial direction. As this fluid flows through the pump, it’s forced against a frontal surface and pushed into higher pressures and greater volumes. Axial flow pumps are often used in industrial processes like manufacturing and oil refining because they can handle high pressures and temperatures.

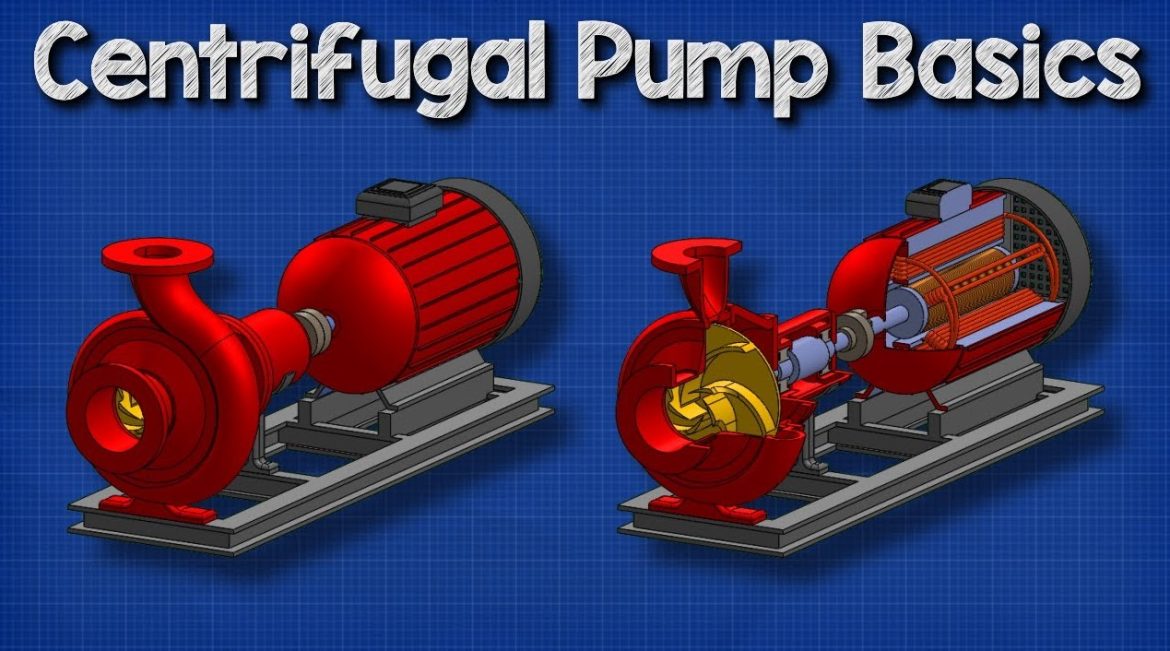

3. Centrifugal pumps: These pumps use rotating disks to move fluids around within a chamber. The disks create turbulence which speeds up the movement of fluid through the pump. Centrifugal pumps are often used in processing applications that don’t require high pressure (like washing clothes).

4. Pneumatic pumps: These pumps use air pressure to move fluids around within a system. Unlike other types of

How do high-pressure pumps work?

High-pressure pumps are used in a variety of industries to move liquids, gases, and powders. They work by using a piston to push the fluid through a pipe at high speed. The higher the pressure, the more fluid can be moved in a given amount of time.

There are several types of high-pressure pumps available on the market, each with its own advantages and disadvantages. Which one is best for your application will depend on factors such as cost, size, reliability, and output.

Some of the most common types of high-pressure pumps include centrifugal, positive displacement (PD), rotary, and piston. Each has its own advantages and disadvantages when it comes to specific applications.

Vertical centrifugal pumps are the most common type and work by using a spinning blade to force fluid through a pipe. They are affordable and relatively small, but their limited output means they aren’t ideal for high-volume applications. PD pumps are similar to centrifugal pumps but use an impeller instead of blades to create force. They tend to be more expensive than centrifugal pumps but have greater output capacity, making them better suited for larger tasks. Rotary pumps use a series of rotating discs to create force; while they are more expensive than PDs and centrifugal, their greater output makes them better suited for high-pressure tasks that require frequent changes in direction, such as spraying or washing fluids. Piston pumps use a piston to push the fluid

Which pump is best for my needs?

There are many pumps on the market today that can be used for high-pressure applications. Choosing the right pump for your needs is important, so here are some factors to consider:

1. Flow rate. The flow rate of a pump is important because it determines how much fluid it can move in a given period of time. Higher flow rates mean faster feeding and pumping, which is good if you need to move a lot of fluid quickly.

2. Pressure rating. A pump’s pressure rating tells you how powerful the motor is and how much pressure it can handle. Pumps with higher pressure ratings can handle greater flows without breaking down.

3. Features. Some pumps come with features such as variable speed or pause/resume operation that make them more convenient to use.

4. Price tag. Finally, price is always a factor when choosing a pump; higher-quality pumps tend to cost more than cheaper models.

Conclusion

If you are looking to use a pump for high-pressure applications, then the Schoeller S6 is a great option. It features an efficient seal technology that helps to prevent leakage and keeps your equipment running smoothly. Additionally, it comes with an ergonomic handle that makes it easy to maneuver.