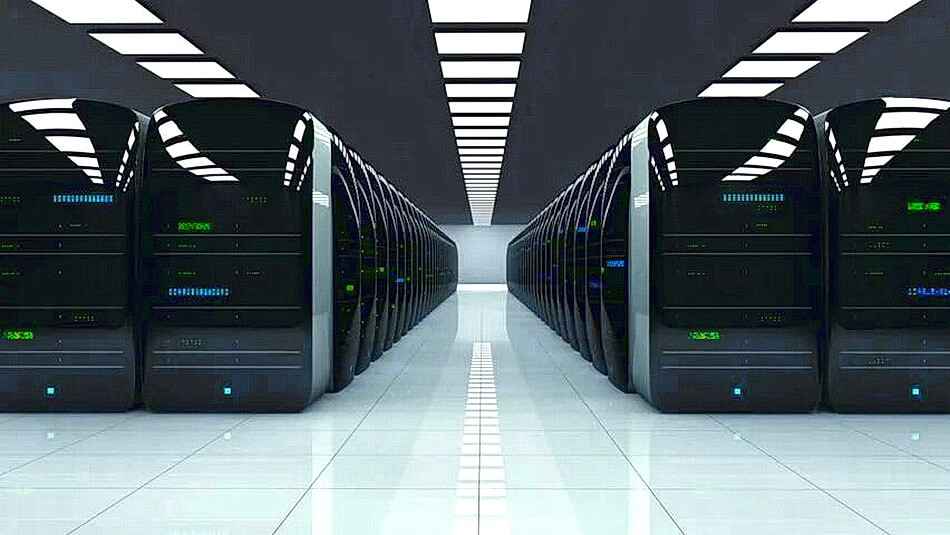

How to reduce and optimize the entire testing phase in the commissioning stage is one of the requests from the industry not only to shorten times. But also, to gain process reliability. It is in the commissioning stages that we test the efficient operation of a data center and it must guarantee, and tested its capacity. We offer best in industry products and services for APC PDU prices in Pakistan.

Are Load Banks Completely Reliable Option

Currently, load banks are almost the only completely reliable option to be able to carry it out. A debate that we have transferred to DCD. So, that engineering companies, cloud operators and manufacturers can provide us with their approach on the subject.

Ensuring The Reliability of Power Equipment in A Data Center

Imagine for a moment that a power outage in your data center caused infrastructure chaos. I eat? draw Possible scenarios. One of them, that the emergency generators could not support the cut in the electricity supply because they did not start.

Here even more hypotheses open to the question of why they did not work. And so, it could extrapolate to refrigeration systems and all those mission-critical systems in a data center.

Efficiency Of a Data Center

Smart load banks allow not only to test the operation of a data center. But also, to push the conditions in which they design to the limit and check their efficiency. In a word, to guarantee the reliability of all the equipment involved in its proper functioning.

Reducing Commissioning Times

With the same equipment it is possible to test all those critical mission systems of a data center, change the delta T and keep the electrical power fixed. In this way, it is possible to test different scenarios of a data center and take the installation “to the limit” without damaging anything.

Management Of Electrical and Energy Resources

It is impossible for some types of facilities, including data centers, hospitals, airports, utilities, oil and gas operations, and railroads, to function without a backup power dependability of one hundred percent.

Even the most basic commercial and manufacturing facilities have backup power systems to ensure that their emergency systems, alarms and controls, emergency lighting, and smoke and fire control systems continue to function as intended in the event of a power outage.

The majority of standby power systems consist of a battery pack in addition to an uninterruptible power supply, often known as a UPS. The uninterruptible power supply (UPS) acts as a backup for the digital control system (DCS), which allows the plant operations to keep under control until shuts down DCS in a secure manner or the standby generator kicks on.

Systems Of Backup Batteries Offering Improved Functionality and Dependability

Even though most of the batteries used in current UPS systems do not require any maintenance, it is still possible for them to get damaged because of corrosion, an internal short, sulfation, drying out, or a breakdown of the seal. This article outlines the recommended procedures to follow to maintain these “battery banks” working at their peak efficiency and ensure that a backup is always prepared if the primary power source fails.

The Two Most Important Markers of How a Battery Is Doing

Resistance on the inside is more of a test of life than it is of capability. The resistance of a battery stays the same up until it is getting close to the end of its useful life. When this happens, the battery capacity will start to drop, and the internal resistance will start to rise. By measuring and maintaining a record of this value, it is possible to determine when it is time to replace the battery.

How to perform standard battery tests

Float Voltage

Remove any connections between the batteries and the charging system as well as the load.

Monthly checks using a digital multimeter or should perform battery analyzer on the voltage of each individual cell or string.

Output From the Charger

Monthly checks using a digital multimeter or battery analyzer. Such as one from the series. Should perform on the output voltage at the charger’s output terminals.

Either use a clamp meter or pay attention to the output current that indicates on the current meter of the charger. Performs the measurement on a monthly basis.

DC Float Current

We recommend it is that you consult the manufacturer’s specifications to get an estimate and predicted values of float currents.

When measuring the predicted float current once a month, use a DC clamp meter that is sufficient for the job.

Internal Ohmic Values

Measure the individual ohmic values of the battery once every three months with the assistance of a battery analyzer, such as one from the Fluke 500 series.

Establish the reference values, and then insert them into the database pertaining to the battery.

Causes of Batteries Failing

- Loose terminal and intercell connections

- Aging

- Overcharge and over discharge

- thermal runaway

- Undulation

Inconsistency being the weakest link

When one battery in a string end, take the entire string out of service. May use the string which shortens the amount of time.

The Worst-Case Scenario

During the discharge process, a battery that has a high impedance level has a greater risk of overheating, starting a fire, or exploding. Measuring the voltage by itself will not provide an indication of this risk.

Overheating is the primary factor that leads to battery failure. When the average temperature rises by 8 degrees Celsius (or 15 degrees Fahrenheit), the lifespan of a battery drops by half.

Because of the way the charger is set up, a faulty battery can cause the charging voltage of nearby batteries to rise, which will shorten the life of the entire string of batteries.

Advantages Of UPS In Data Centers

Increasingly often, commissioning – or commissioning – teams are looking for smart load banks that allow them to:

- Control Delta T

- Record The Data

- Simulate, As Realistically as Possible, The Future IT Load

In addition, one of the main advantages of its use in data centers is that it allows reducing the commissioning time of a data center, making the entire commissioning phase more efficient and real.

Conclusion

We will talk about all this on together with the main players in the industry at the Smart Load Banks Panel for commissioning in data centers.

Come with us to find out in depth what the tests of a load bank include in the commissioning phase. What are the deadlines to obtain a complete load test or how to apply its use in new equipment.

To Find the Best Prices Visit Our Official Website: APC Distributor in Pakistan