Many times there is confusion about what it takes to finish a standard process and whether or not SMT PCB assembly worth the cost. This article will provide you with an overview of how much it costs to assemble a PCB and what steps are involved in the process of making that PCB.

What is SMT?

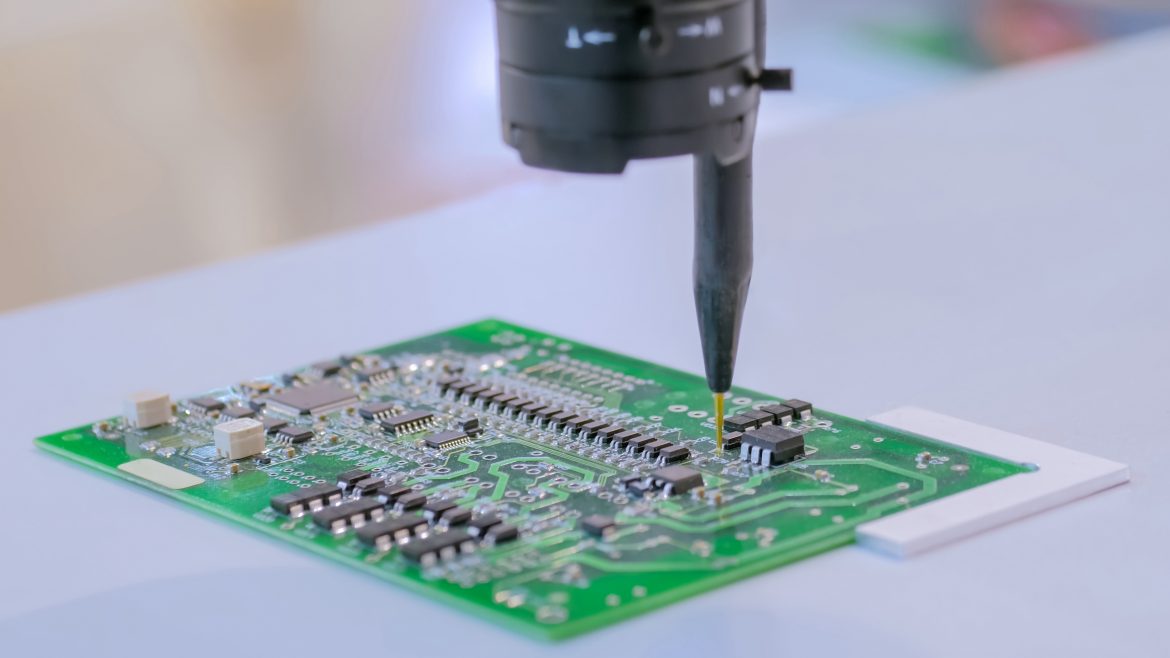

SMT, or Surface Mount Technology, is a type of PCB assembly that uses small circuit boards with many components soldered onto them. The benefits of SMT over traditional PCB assembly are lower manufacturing costs and faster production times. Traditional PCB assembly can be time-consuming and expensive, requiring skilled technicians and high-quality tools. SMT also allows for customizations not possible with traditional PCB assembly methods.

The process of SMT PCB assembly begins by creating a design file using a CAD software package. This design file will include the layout of the circuit board. As well as the placement of each component on the board. Next, the components must be ordered from an appropriate supplier. Once the components have been received, they must be properly tested and then installed onto the circuit board. Finally, the final steps of testing and packaging are completed to complete the SMT PCB assembly process.

The overall cost of assembling a standard SMT PCB can be significantly lower than traditional. PCB assembly methods due to savings in tooling costs and manufacturing time. However, there are still some important costs associated with SMT. PCB assembly that must be accounted for if accurate pricing is desired. These costs include test equipment needed to verify each component’s function. As well as packaging supplies necessary for shipping finished products to customers.

PCB Assembly Cost

PCB assembly cost can vary widely depending on the complexity of the PCB design. The number and type of components included, and the manufacturing process used. In this article, we’ll provide an overview of the three main types of PCB. Assembly processes and discuss their associated costs.

Inkjet printing: Inkjet printing is a relatively new type of manufacturing process. That uses small jets to print patterns onto thin sheets of plastic. Because inkjet printing is so versatile, it’s often used to produce custom ICs, circuit boards, and other electronics parts. Inkjet printing costs tend to be higher than other types of PCB assembly because it requires more sophisticated equipment.

Why a Good PCBA Manufacturer is Crucial

A good PCBA manufacturer is crucial to the success of a PCB assembly project. The right PCBA manufacturer can help reduce costs and speed up the assembly process. Here are four reasons why a good PCBA manufacturer is important:

1. Good quality control – A good PCBA manufacturer will have a high level of quality control. When it comes to their manufacturing processes. They will make sure that all the components they produce are of the highest quality. Which will help ensure that your PCB assembly projects run smoothly and without any errors.

2. Rapid production times – A good PCBA manufacturer can produce PCBs quickly and efficiently. This is important because it can reduce overall assembly time by allowing you to get your project finished faster.

3. Reduced waste – A good PCBA manufacturer will be able to reduce the amount of waste. That they produce during PCB assembly projects. This is because they will be able to find ways to reuse or recycle materials. Instead of throwing them away unnecessarily.

4. Cost savings – A good PCBA manufacturer can help you save money on your PCB assembly projects. By reducing costs associated with manufacturing processes and equipment.

Tips for Creating the Finest SMT PCB

The cost of manufacturing a small PCB (printed circuit board) can be deceiving. To create the finest SMT PCBs. It is important to know what it takes to put the right components on a PCB.

The following tips will help you save money and produce flawless SMT boards:

1. Use the Correct Board Format

When selecting a PCB format. Make sure that the dimensions of your board are compatible with those of your target equipment. Some popular formats include 0.8 inch (2.13 cm), 1.27 inch (3.50 cm), and 2 inch (5 cm).

2. Choose Quality Components

Selecting quality components is essential for producing a high-quality SMT board. Make sure to choose parts that are compliant with your target. Equipment specifications and have been tested in accordance with industry standards.

3. Plan Your Assembly Process Carefully

Planning your assembly process carefully will help ensure that your SMT boards are defect-free and meet your specific requirements. Proper assembly techniques include using proper soldering techniques, aligning components correctly, and verifying component placement before soldering connections together

Conclusion

In this article, we will be discussing the SMT PCB assembly cost. And what it really takes to put the right components on a PCB. There are many factors that go into calculating an SMT PCB assembly cost. Including the complexity of the component. How difficult it is to assemble the component onto the board. And whether or not other parts need to be sourced separately. In order to get accurate costs for your project, it is important to have clear specifications from your customer. Do not rely solely on quotes provided by suppliers; instead. Contact them directly and ask for additional information so that you can provide an accurate quote.