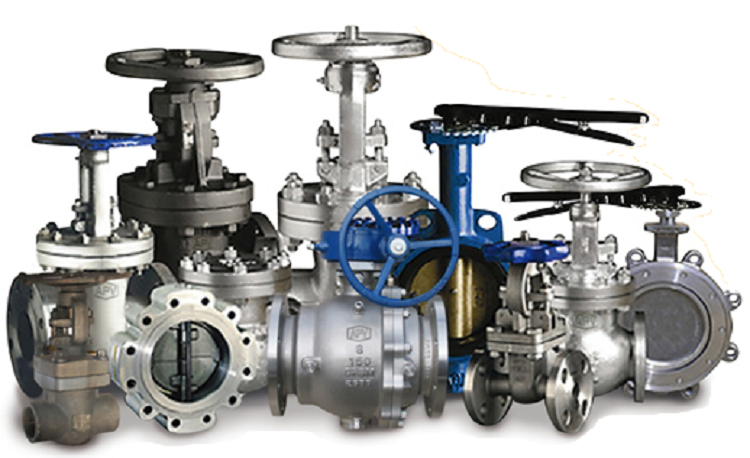

Valves are mechanical equipment that is positioned in fluid systems that allow you to regulate, stop, and restore the flow of fluid through an application. Plumbing valves come in a wide range of varieties with several applications. Whether you’re designing an industrial pipe network or repairing a household’s plumbing, it’s important to know the types of valves your system requires.

Your system will run more smoothly if you install the valve that is best for your application, which you can do by learning which valve type to use. Globe valves, gate valves, and ball valves are the three types of valves that are use the most frequently. In this article, we’ll look at some of the most common applications for these valves as well as the valves themselves.

Globe Valves vs. Gate Valves vs. Ball Valves

How do you determine which valve type to employ for your application when there are so many different varieties available? When choosing the type of valve to utilize for your application, it is important to be aware of these distinctions. The features and functions of each type of valve are cover below.

Globe Valves

One of the most popular types of valves used in industrial settings is globe valves. They are categorize as linear motion valves, which implies that the valve’s opening and shutting to the fluid flow is accomplish by a movable plug that moves perpendicularly. The fact that globe valves are effective at managing flow in high-pressure applications, high temperatures, or particularly viscous mediums makes them a common fixture in power plants and other industrial settings.

How does a globe valve work?

Globe valves were the de facto norm for control valves for many years. Since the two sides of the body are divid by an internal baffle, they are named for their spherical body form. The valve can be close by screwing movable plus or discs into an aperture that creates on the seat of the device. Instead of threaded stems, the majority of automated globe valves function by using an actuator assembly to open and close.

Application

Globe valves can be beneficial in a number of scenarios, including those in which flow must be regulate but not at a constant rate. They are suitable for applications that demand a safe, leak-proof, corrosion-resistant solution. Globe valves are more expensive than gate valves due to their capabilities, but they are a worthwhile investment in some situations.

Gate Valves

Gate valves are sometimes referred to as “multi-turn valves” because they need many 360-degree turns of the handwheel to open or close the valve. Due to their poor throttling capabilities, they are regard as shutdown valves as oppos to control valves. Gate valves offer a tight shutdown and are thus frequently employed for media isolation. Gate valves don’t compel the medium to shift direction (as a globe valve does), hence they don’t create much of a pressure drop.

How does a gate valve work?

One of the first valve designs, the gate valve, is best suite for on-off, predominantly liquid, operation. For a gate valve to work, a rectangular or circular gate must be raise out of the fluid’s flow. Gate valves are full bore when fully opened, which means nothing is obstructing the flow as the pipeline diameter and the gate diameter have the same opening. The valve size is also influenced by this bore diameter. The exceptionally low friction loss of this fullbore design is a benefit that lowers the total cost of ownership and conserves energy.

Application

The gate valve, which is distinguished by a wedge-shape disc, is frequently used to isolate media since it has a high degree of sealing ability. In situations when a tight seal is require, this type of valve might be employ. In a thicker and more viscous medium, a unique type of gate valve called a knife gate valve is utilize.

Ball Valves

A ball valve features a spherical disc that may be opened, closed, or just partially open to regulate the flow of fluids (liquids, gases, and slurries). Solid-element ball valves have exceptional longevity and the capacity to keep working properly even after extended periods of inactivity. It features a spherical insert inside the conduit that is compose of stainless steel, chrome-plated brass, or brass.

Another prominent type of ball valve is the automatic ball valve. Motorized ball valves are automate water flow control valves. The actuated ball valves are usually reliable and long-lasting, shutting firmly even after many cycles or extended periods of inactivity. Due to its special qualities, motorised ball valves are a significant investment for shut-off and flow regulation applications.

How does a ball valve work?

Ball valves have a ball inside the valve. A ball valve is a type of quarter-turn valve that controls flow through it using a hollow, perforated, and rotating ball known as a “floating ball.” When the ball’s hole is parallel to the flow, the valve is open; when the valve handle pivots the ball 90 degrees, the valve is close. The handle allows for simple visual confirmation of the valve’s condition since it sits flat in line with the flow when the valve is open and perpendicular to it when it is close.

Application

Due to its simplicity of use and upkeep, the ball valve is one of the most often utilize in both home and commercial applications. It is also a very adaptable valve that may be use for a variety of tasks, including managing water flow in a plumbing system and controlling the oil flow in an oil refinery.

Valve Type Pros and Cons

| Valves | Pros | Cons |

Globe | Fast-acting capabilityCan regulate media flowAble to handle media that is corrosive, viscous, high-pressure, or temperatureGood shutoff capability.Easy to maintain and resurface the seats.Low chance of leakage | Ample space for disc assemblyMore substantial than other valvesAdd resistance to the media flowLower close-off rating than other valves especially in larger sizes. |

Gate | Pose minimal resistance to media flowSuitable for use with viscous liquids and slurriesUsed as a shut-off valveEasy to maintain and disassembleCost-effectiveInherently fire-resistant (when used with a metal sheet)Multidirectional | Low-pressure constraintsSlow opening and closingGreater propensity for corrosionCan lead to water hammer.Leak-prone and less robust than ball valves |

Ball | Excellent for high volume, high pressure, and high-temperature flowRobust and reliableLow cost of acquisition and maintenanceAllows for the examination and replacement of seats and seals without removing the valves’ bodies from the line.Requires no lubricationHigh flow capacity and negligible pressure drop.Pose minimal opposition to media flow | Low throttling capabilitiesContamination due to difficulty in cleaningIneffective for controlling the flowWater hammer might result from a fast cycle time. |

Bottom Line

Choosing the correct valve for the job at hand is sometimes important since improper use can have disastrous effects on safety, finances, and the environment. When selecting the ideal valve for a particular application, several factors must be carefully taken into account, but generally speaking, the selection procedure aims to match the valve’s functioning with its intend use.

Gate, ball and globe valves are widely used in residential, commercial, municipal, and industrial settings for isolation (on/off) and throttling (flow control) applications. Choose a reputable industrial valve manufacturer in India and conduct thorough research before making any decisions when looking for a valve for commercial or industrial usage.

In order to meet the constantly growing demands of customers, Emechmart is please to offer you a wide selection of gate, ball, and globe valves. If you have any questions about a valve or do not see one that matches your needs, please contact Emechmart right away.